Key Considerations for VAV System Design, Construction, and Commissioning

The proper design and construction of the VAV ductwork system are critical to ensuring the normal operation and control of the VAV system during its later stages

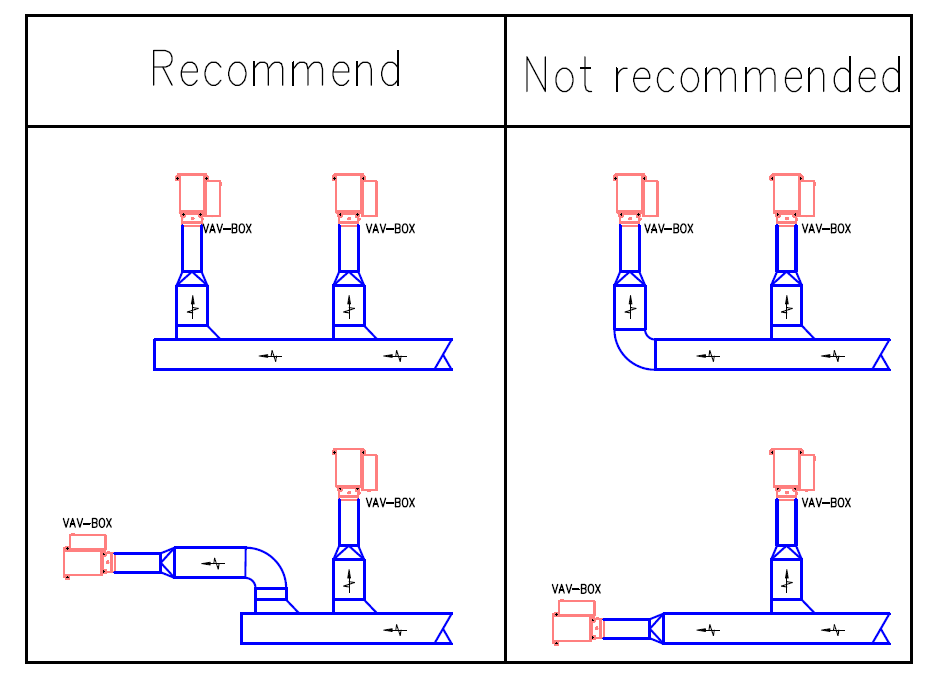

01. Connection Methods of VAV-BOX Branch Ducts and Main Ducts

a.The branch-to-main duct connection for VAV-BOX units adopts a lateral tapping method (see Figure 1). This configuration ensures more uniform inlet static pressure across all VAV-BOX terminals, significantly simplifying system commissioning.

Figure1

b.The branch duct interface shall have a 45° transition angle or rounded edge. The branch duct must not protrude into the main duct, and the connection must be free of burrs. Refer to Figure 2 for the connection method.

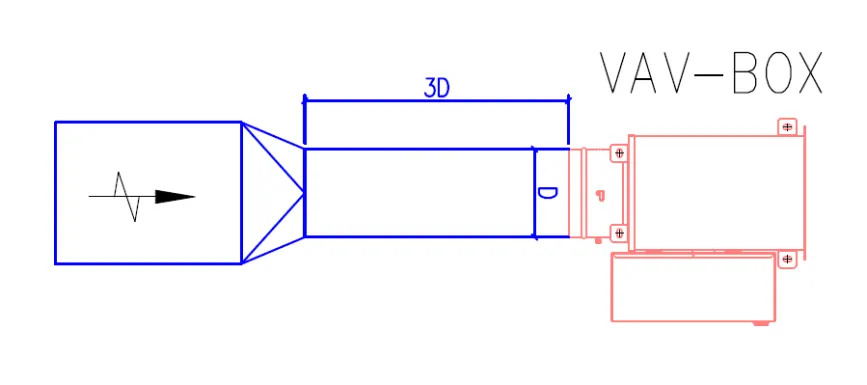

To ensure accurate measurement of the actual supply airflow, the straight duct section upstream of the VAV box must generally be no less than 3–5 times the inlet diameter.

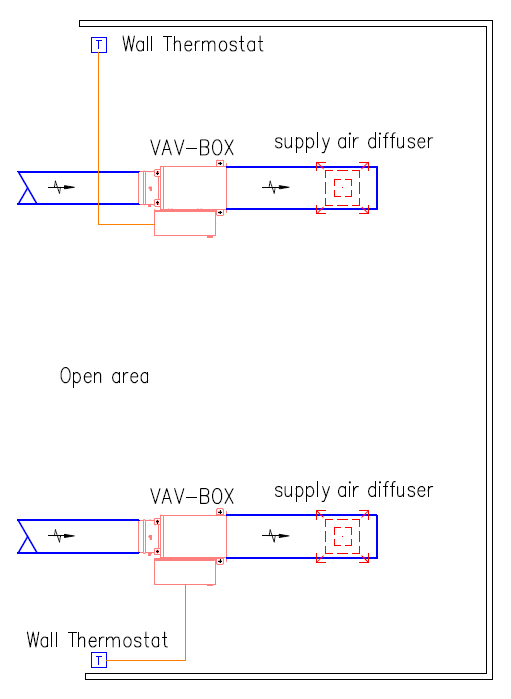

Unless otherwise specified, each VAV-BOX controller is configured with a thermostat to monitor room temperature. During the design phase, the thermostat locations must be finalized and coordinated with the interior design and electrical engineering teams. This prevents the thermostats from being clustered in a single area during installation, which could result in significant temperature measurement inaccuracies.

RS Project: Changsha

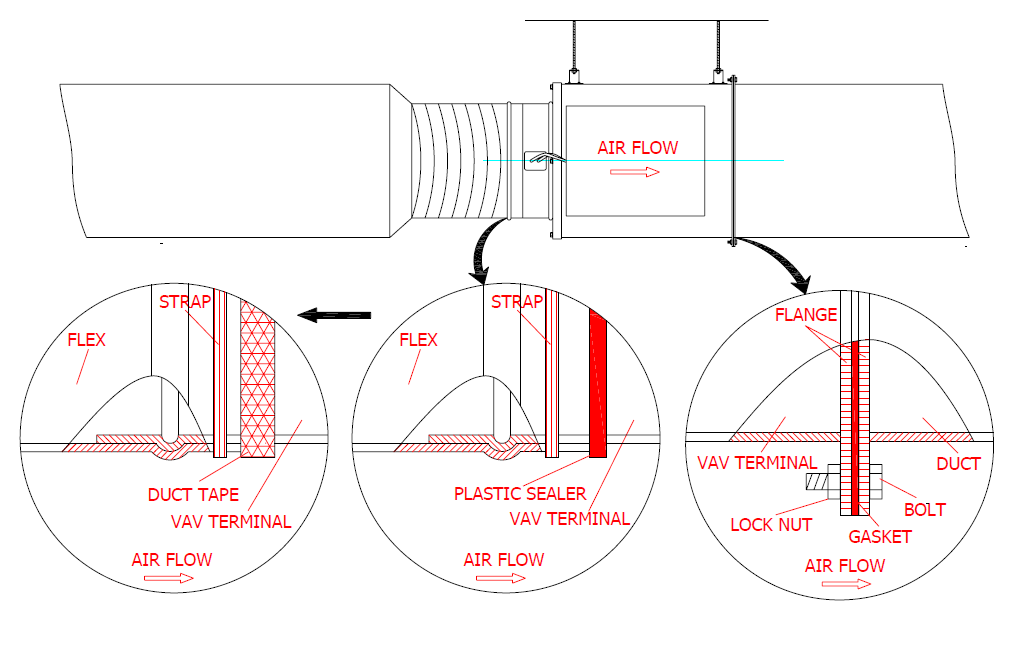

02. The Connection Methods of VAV-BOX

Improper field installation of VAV terminal unit connections may result in excessive air leakage and subsequent commissioning difficulties.

The straight pipe section of the inlet connection should be sleeved over the air inlet of the VAV-BOX, secured with 4–6 self-tapping screws, and sealed with silicone at the joints to prevent air leakage, followed by external insulation. The circular inlet section of the VAV-BOX also requires external insulation.

When the VAV-BOX outlet adopts a flange connection, the flanges of the VAV-BOX and the air supply duct should be aligned with a sealing strip attached and then fixed with bolts to prevent loosening and air leakage.

RS Project: Shanghai

Q&A

Key Points for VAV-BOX Commissioning

Q1: In many projects, a standard power-up test is performed upon receiving VAV-BOX units. However, when the unit is powered up in isolation (without duct connections), we observe a consistent pattern: the damper remains in a fully open position regardless of the thermostat ON or OFF. Is this behavior normal?

A1: Yes. This is standard operation for most VAV controllers. The control logic is designed to maintain minimum airflow setpoints when the thermostat is in OFF mode. In this isolated test configuration (without duct connection), the measured supply airflow registers 0 CFM - below the minimum required threshold - which triggers the damper's failsafe position of full open.

RS Project: Jinan

When performing standalone commissioning, the following parameters should be monitored to verify proper VAV-BOX operation:

1.Actual Airflow

2.Target Airflow

3.Damper Position

4.Operating Mode

5.Zone Temperature

6.Temperature Setpoint

Common Issues During Standalone VAV-BOX Commissioning

Q1: After confirming proper actuator rotation direction and validating temperature setpoint accuracy, why does the VAV-BOX damper remain inoperative?

A1:

When the measured airflow significantly exceeds the commanded airflow setpoint, this indicates a static pressure sensor failure in the VAV-BOX control system.

Check whether the static pressure air duct and the air velocity sensor nozzle of the VAV-BOX are detached and leaking. Replace any damaged parts.

Q2: Why is the VAV controller unable to measure airflow?

A2:

Check the air velocity sensor nozzle and tubing for air leaks or blockages.

Verify the high/low pressure tubing connections are correctly installed on the controller (not reversed).

RS Project: Guangzhou

Every step matters in creating superior VAV systems - from precise engineering designs to flawless installation and optimized performance tuning. With five decades of focused innovation in VAV technology, Royal Service Air Conditioning has built an unmatched reputation in our field. We remain committed to continuous innovation and the pursuit of excellence, developing products that meet market demands and earn customer recognition.